Moisture Separators

- Home

- Moisture Separators

Moisture Separators separate out the liquid mechanically which Condense during cooling in the After cooler, or Re condense due to change in temperature.

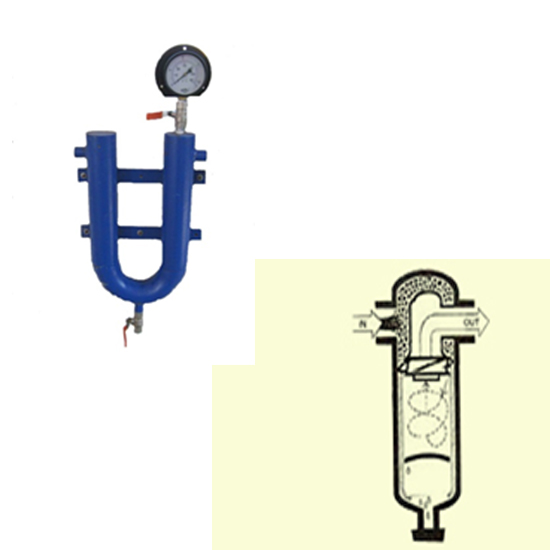

Here, Mechanical Separation takes place, by change of flow direction (baffle type) or by Centrifugal action (Centrifugal type), or combination of Both types (as seen in the figure). Baffle type Separators are simple devices, ideal for coarse Separation and are generally supplied along with the After cooler, Centrifugal type is more efficient Because of its cyclonic action. Demister Pads (for Removing fine mist) in the outlet further enhance the Separation efficiency. Separated liquids effectively drained by manual valve or auto drain valve. Auto Drain valve is better choice for effective drainage in time repeatedly.

1] ‘A-1’ Make Moisture Separator : – It is state of art moisture trapper, which has got twin separation effectively remove moisture content from humid compressed air. The air with heavy moisture particles is guided to collide and chopped with special effect of poly tips inside to form droplets from fine moisture-mist.

In 2nd stage, this air is forced to pass through S.S element of fine demister pad in zigzag path to further separate fine mist particles. The droplets thus separated is collected in bottom part which is connected with manual drain valve for regular flush out of separated liquid.

The automatic drain valve can be provided for more better performance of the system, as it ensures regular interval of draining at pre set timing of say every 30 minutes for 4 seconds or as per your need.

In Mechanical type float auto drain, when water accumulates, level rises and float valve accordingly open up to pass water through drain opening. A manual drain is also provided for safety.

Benefits of A-1” Moisture separator:-

- Better quality & consistence performance of Separator unit as made from quality material.

- Most Reliable and Enhance the Final Quality of product.

(c) Elimination of accidental down time risk likely due to poor quality of product.

- It is far economical then failure cost of the machine / System of the plant.

- Secure life of m/c. As after sales, service & spares support.