Piping

- Home

- Piping

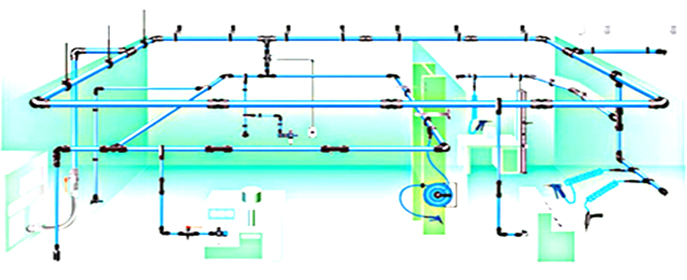

Industrial Piping is most neglected area due to casual approach and unnoticed LEAKS which causes power wastage, due to poor workman ship, improper sizing, illogical layout & poor material selection.

The havoc of leak : It can be judged by following effect of Leakage :-

- ( I ) Leak of : 1 drop/seconds = wastage of 8640 Liters/year

- ( II) Leak of : 1mm Hole @ 6 bar Pressure = wastage of 3838 power units (KWH) /year

We are well experienced in perfect leak proof piping solutions for all major industrial Uses. The aim is to provide guaranteed services with “best pipe engineering” to Industry. In various material like: PPRC, M.S, G.I , S.S , Aluminum , Copper, HDPE etc.

Industrial Piping is most neglected area due to casual approach and unnoticed power wastage, due to poor workman ship, improper sizing, illogical layout & poor material selection.

The havoc of leak : It can be judged by following effect of Leakage :-

( I ) Leak of : 1 drop/seconds = wastage of 8640 Liters/year

( II ) Leak of : 1mm Hole @ 6 bar Pressure = wastage of 3838 power units (KWH) /year

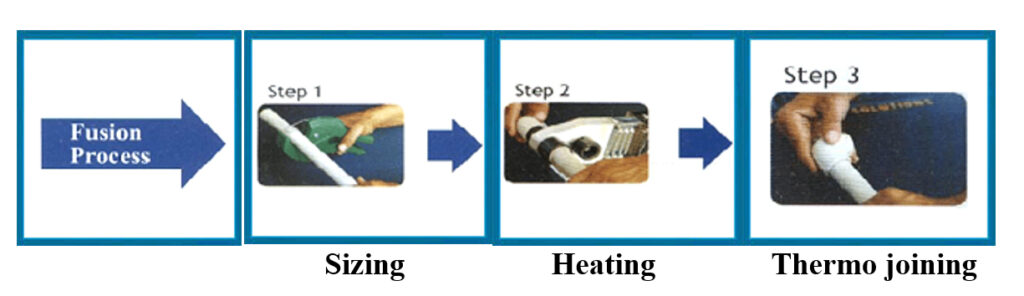

We introduce the Zero leak ‘FUSION’ plumbing solution. The German concept of PPR piping.

PPR means Polypropylene Random Co polymer.

What is a PPR pipe? What are it’s advantages and uses?

PPR =Polypropylene Random Copolymer

-PP-R pipes is made with reference to the standard of DIN8077/8078 of Germany.

We serve efficiently to transport the followings fluids in the close loop system with all down line Instrumentations, controls & Flexible Rubber , P.U, pipe & connections with temperature, pressure indicating gauges :

- Compressed air, O.D: 20 to 310 mm ( ½” – 12” Nb ) Pressure: 70 Kg/cm2

- Drinking & Processed water ( Chiller, Cooling tower, R.O, D.M, Waste etc. )

- Temp. – 5 degree C to 90 deg.C for PPRC

+ 600 degree C for Steam.

- Gases: LPG, Nitrogen, Oxygen etc. [ With Instrumentation & Controls ]

- Steam, Vacuum (suction pipe), [ With Required accessories & Insulation ]

- Liquid : Fuel, oil, syrup, chemicals [ Food quality, chemical resistance pipe ]

1 DISTRIBUTION PIPING: (IN CLOSE LOOP)

SCOPE:

A-1 Air & Gas Co is well experienced in perfect piping solutions for all major industrial Uses. The aim is to provide guaranteed services with “best pipe engineering” to Industry. We serve efficiently to transport the followings fluids in the close loop system with all Down line Instrumentations, controls & Flexible end connections with temperature, pressure Volume indicating accessories:- Compressed air, Outer Diameter: 2000 mm O.D, 70 Kg/cm2 working pressure.

- Drinking & Processed water ( Chiller, Cooling tower, R.O, D.M, Waste etc. )

- Temp. – 5 degree C to 90 deg.C for PPRC + 600 degree C for Steam.

- Gases: LPG, Nitrogen, Oxygen etc. [ With Instrumentation & Controls ]

- Steam, Vacuum (suction pipe), [ With Required accessories & Insulation ]

- Liquid : Fuel, oil, syrup, chemicals [ Food quality, chemical resistance pipe ]

- M.O.C : PPRC, S.S-304, S.S.- 316, M.S, Sch.40, sch. 80, G.I etc.

APPLICATIONS:

- Residential cold and hot water system

- Underground heating system

- Conveyor of industrial water and chemical materials

- Sanitary and pure water pipelines

- Hot water recycling system

- Compressed air pipelines

- Drink manufacturing and conveying system

- Other industrial and agricultural pipelines

Polypropylene random copolymers are thermoplastic resins produced through the polymerization of propylene, with ethylene links introduced in the polymer chain. The resins possess a broad range of characteristics and are used in a wide range of applications.

Standard Size : Outer diameter size: 20 mm to 310 mm (½’’NB to 12”NB )

Standard Length : 3 Mtr.[10 feet]

Working pressure : 20 Kg/cm2. Max.

Temperature : – 5 Deg. C to + 95 Deg. C

Uses : Compressed air, Cooling tower, Chilling plant, AHU plant, Hot water, Drinking water, Water pump, Food & beverages, Dairy, Swimming pool, Water park, Industrial, residential and commercial liquid distribution usage, Chemical, acid, ETP, pharmacy, Solar system, R.O plant, D. M. plant, Fuel line, Edible & Mineral oil etc.

Which gives unique properties like –

- Good mechanical strength, Food grade, non corrosive safe material.

- Very less insulation is required as very less thermal energy loss.

- Very smooth Inner surface, very less frictional loss,

- Required less Power Input of water pump for more delivery, Thus power saving.

- Can be successfully used up to 20 % acidic chemicals.

- Safe for drinking water, Process water, R.O water, D.M Water.

- Reliable leak free jointing with longer service life